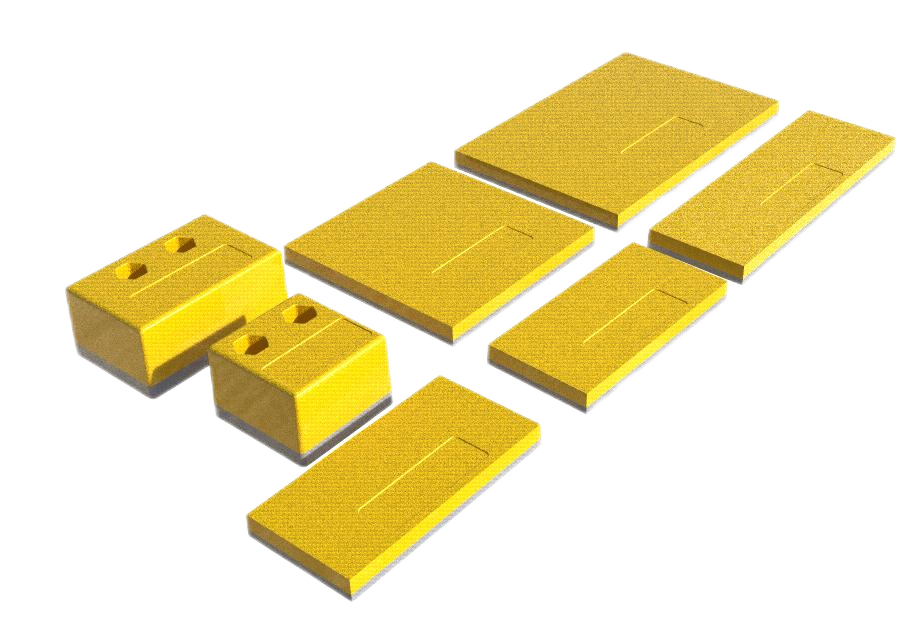

Heavy-Duty Bucket Teech with Embedded Tungsten Carbide Overday

Hedi specialized in producing and designing for excavation, mining, or construction bucket teeth. The bucket teeth are reinforced with tungsten carbide—an ultra-hard, wear-resistant material—to extend their lifespan in harsh environments.

Key Features

-

Tungsten Carbide Overlay (TCO):

- A layer of tungsten carbide particles is welded or embedded onto the surface of the teeth.

- Resists abrasion, impact, and corrosion from rocks, gravel, and other abrasive materials.

-

Heavy-Duty Construction:

- Made from high-grade steel with reinforced designs (e.g., dual spikes, wide profiles) for demanding tasks like mining or quarrying.

-

Replaceable Design:

- Teeth are often bolted or pinned to the bucket edge, allowing easy replacement when worn.

Applications

- Mining: Drilling, digging through hard rock or ore.

- Construction: Trenching, site preparation, or handling rocky soil.

- Demolition: Breaking through concrete or asphalt.

- Waste Management: Shredding or sorting heavy debris.

Advantages

- Extended Lifespan: Tungsten carbide reduces wear by up to 5x compared to standard steel teeth.

- Cost-Efficiency: Longer service life reduces downtime and replacement costs.

- Improved Performance: Maintains sharp edges longer for efficient digging.

Considerations

- Cost: Tungsten carbide teeth are more expensive upfront but offer long-term savings.

- Compatibility: Ensure the teeth match your bucket model (e.g., Cat, Komatsu, Hitachi).

- Material Suitability: Best for extreme abrasion; overkill for light-duty tasks.

Please contact sales@hedicorp.com for E-Catalogue